Pharmaceutical

Geiger has extensive experience meeting the strict compliance demands of process equipment sanitary standards in the pharmaceutical industry. We understand that in addition to providing reliable operation that meets the functional needs of the application, installed equipment must meet exacting requirements for hygienic operation and easy, repetitive, routine cleaning. Process efficiency, minimized downtime, and ease of hygienic maintenance are all critical factors required for successful plant operation.

Working with premier sanitary equipment manufacturers, Geiger is pleased to provide reliable and compliant solutions for pharmaceutical plant operations in the Mid-Atlantic region.

Key Applications:

Pill Slurries, Filling Machines, Medicinal Chemicals, Creams & Ointments, Syrups, Injectables, Ultrafiltration, Blood & Plasma Processing, Utility and Plant Services

Highlighted Products

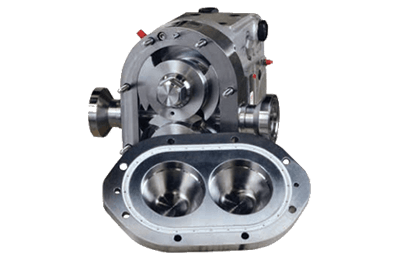

Ampco ZP3 Aseptic Series Circumferential Piston Pump

- Fully CIP Capable – No Need to Tear Down Pumps Daily

- Aseptic Fittings

- Easy to Install One Piece Cover Gasket

- Standard ZP3 Seals with Hardened Seal Faces to Generate Less Heat

- Stainless Steel Bearing Retainers

- Stainless Steel Gearcase

- Stainless Steel Splash Plate Protection

- 17-4ph Shaft with 3X the Strength of 316SS

- Alloy Non-Galling 88 Rotors

- Helical Gears for Extra Strength and Quieter Operation

- Anti-Microbial Lube with Sanitary Gasketed Stainless Steel Cleanout Plugs

- Versatile 4 Way Mounting Configuration

- Multiple Access, Threaded Grease Zerks

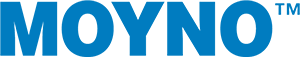

Moyno Progressing Cavity, Sanitary Pumps

- Low-Shear, Non-Pulsating Sanitary Pumps Transfer with Minimal Turbulence or Stress

- Meet 3A and BISSC Sanitary Requirements with No Modifications

- Progressing Cavity Design Results in Minimized Product Degradation

- Non-Turbulent Flow Excels at Handling Shear-Sensitive Products

- Close-Coupled and Open Throat Models Available

- Long Lasting Performance Even for Abrasive Slurries and Corrosive Fluids

- Standard Mechanical Seals Eliminate Product Leakage

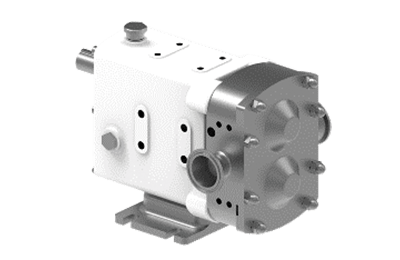

Wright Flow Technologies Revolution Series Sanitary Pump

Wright Flow Technologies Revolution Series Hygienic Positive Displacement Pumps bring clean and efficient pumping technology to a new level.

- Circumferential Piston or Rotary Lobe Design

- Standard, Efficient Clean in Place Ability

- Self-Draining Pump Head

- Innovative Seal Design with No Dead Zones and a Dynamic Leak Path

- No Dead Zones on Front Cover

- Fast, Front Loading Seal Changes While Pump Remains in Line

- Front Access Shimming for Setting Rotor Clearance

- Gentle Handling of Solids and Shear Sensitive Liquids

- Long Life Durability from Heavy Duty Shafts, Bearings, and Helical Gears

Key Products

- Ampco Sanitary Pumps - Sanitary Positive Displacement & Centrifugal Pumps

- Flux - Sanitary Drum Pumps

- Goulds - Heavy Duty 3196 i-Frame Process Pumps

- Goulds - Heavy Duty 3400 Series Horizontal Split Case Utility Service Pumps

- John Crane - Hygienic Vessel, Mixer and Agitator Seals

- Flowserve - Pharmaceutical Ready Mixer Seals

- Gasho - Vacuum and Booster Systems

- Moyno - Sanitary Progressing Cavity Pumps

- Versamatic - FDA Compliant Air Operated Double Diaphragm Pumps

- Wright Flow Technologies - Hygienic Positive Displacement and centrifugal Pumps

- Warren Rupp Sandpiper - FDA Compliant Air Operated Double Diaphragm Pumps

Contact us to discuss your application