Refineries

Geiger has developed in-depth knowledge and expertise to serve the oil and gas industries. The market is typically divided into upstream, midstream and downstream elements and encompasses oil and gas processing from extraction, through transfer and storage and ultimately processing in the refining industry into intermediate stocks used in industry and end products to be used by consumers. Pumps are used extensively to transfer, inject, load, and unload raw materials, intermediates, and end products. Mechanical seals are used to contain leakage along an equipment’s rotating shafts of both hazardous and non-hazardous materials throughout the refining process.

Key Applications

Product Unloading, Blending, Injection-Secondary Recovery, Ammonia Transfer, Boiler Feed, Condensate, Cryogenics, LNG Transfer, Cooling, Sump Wastes, Molten Sulfur, Tank Unloading, Corrosive and Non-Corrosive Liquids, Service Water.

Highlighted Products

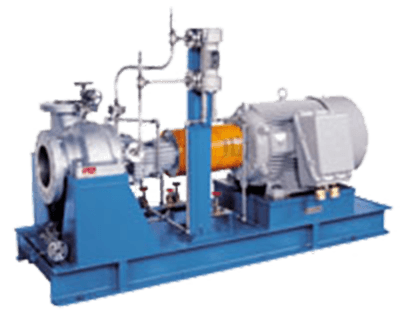

Goulds 3700 API 610 12th Edition / ISO 13709 2nd Edition, OH2 Overhung, Radially Split, Single Stage Process Pump

Goulds Pumps, Model 3700, High-Temperature, High-Pressure End Suction Process Pumps meet or exceed API610, 11th Edition / ISO13709 2nd Edition, and are available in a wide range of materials and hydraulic coverage. These Pumps come standard with a proven API 610 Nozzle-Load Design, Full Flange Rating Pressure Capability, and Spiral Wound Casing Gasket. Optional designs are available for solids handling and fully API compliant low flow services.

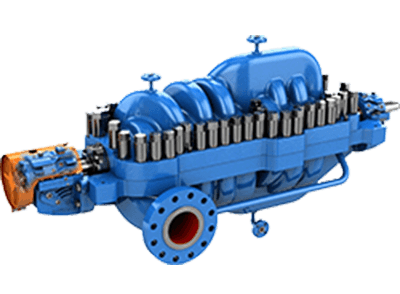

Goulds 3600 i-FRAME® API BB3 Between Bearing, Axially Split, Multi-Stage Process Pump

Goulds Pumps, Model 3600, is designed for High-Head, High-Capacity Services over a broad range of hydraulic services. Pumps are a Dual Volute Design with Axially Split Casing, Heavy Duty Single Row Bolting, Precision Cast Impellers, Compact Crossover, and i-FRAME Bearing Housing features including Bearing Housing Filter and a revolutionary Oil Capture and Delivery System.

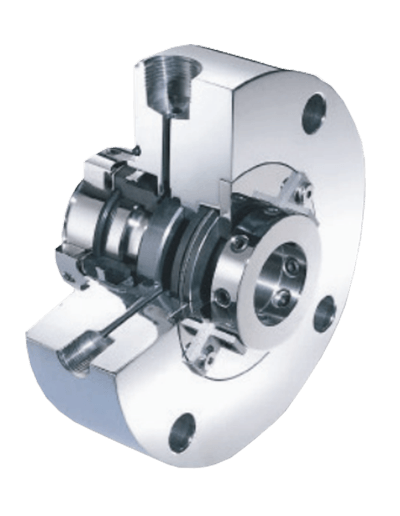

John Crane API 682, Type A, Category 2 and 3, High Performance, Low-Emission Pusher Seal

John Crane, styles 1648, 2648 and 3648 High Performance, Low-Emission Pusher Seals are well suited for a broad range of refinery services. They are available in Single (1648), Dual Un-pressurized (2648) and Dual Pressurized (3648) versions and in both the Style 2648 and 3648, Dry-Running and Gas Lubricated Secondary Containment Seals are available.

Key Products

- ANSI End Suction - Goulds 3196 i-Frame Process Centrifugal Pumps

- AODD - Warren Rupp Sandpiper Signature Series AODD Pumps

- BB3, Axially Split - Goulds 3600 API BB3 Axially Split, Multi Stage Process Pump

- Horizontal Split Case - Goulds 3400 Series Horizontal Split Case Single Stage Pumps

- Horizontal Split Case - Goulds 3316 Two Stage Horizontal Split Case Pumps

- Mechanical Seals - Flowserve High Temperature Pump Gas Seals

- Mechanical Seals - John Crane High Performance Cartridge Seals

- OH2 API 610, Radially Split - Goulds 3700 OH2, Radially Split, Single Stage Process Pump

- Progressing Cavity - Moyno 2000 Series Progressing Cavity Pumps

- Submersible - KSB Amarex Submersible Pumps

- Vertical Turbine - Goulds Vertical Turbine Pumps

- VS4 API Vertical Sump - Goulds API 3171 VS4 Vertical Sump Pumps

Contact us to discuss your application