Food & Beverage

Geiger has a proven track record of meeting the needs of food and beverage industry customers in the mid-Atlantic region. Our team develops reliable solutions with the best hygienic pumps and pump packages available. We will help your food and beverage facility maintain the highest standards, promoting hygienic conditions and preventing contamination. Pumps are available with EHEDG Certification and built in conformance with 3A Sanitary Standards.

Key Applications:

Chocolate Transfer Pumps, Peanut Butter Pumps, Edible Oil Pumps, Food Additives Pumps, Paste Pumps, Liquor Pumps, Syrup Pumps, Molasses Pumps, Dye Metering Pumps, Flavoring Metering Pumps, Glycerol Pumps, Coolant Circulating Pumps, Heat Transfer Fluid and Glycol Circulating Pumps, Sanitary Pumps, Vacuum Pumps, Pneumatic Conveying

Highlighted Products

Viking Pump O-Pro™ Barrier, Guard & Cartridge Mechanical Seals

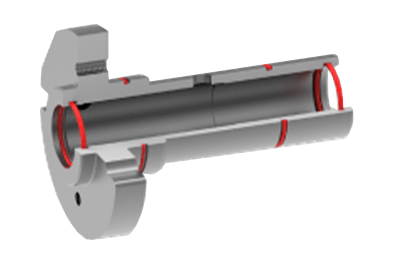

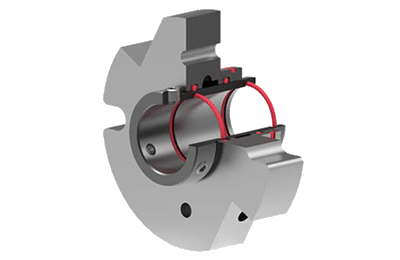

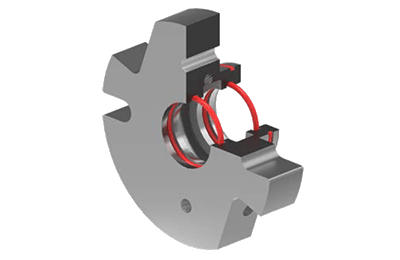

Designed for use in Viking Heavy Duty Pumps, the three styles of Viking’s O-Pro™ Seals replace traditional packing and mechanical seals, using a series of O-rings to create a robust seal and lubrication chamber, all in one.

The O-Pro™ Barrier Seal

The O-Pro™ Barrier seal, combines a hardened bracket bushing with seal gland and double O-ring seals, to prevent process fluids from entering the bracket and eventually leaking from the pump.

The O-Pro™ Guard Seal

The O-Pro™ Guard seal is a compact design providing seal gland, sleeve and double O-Ring seals for an easy retrofit answer for a leaking pump. Stainless steel construction provides wide ranging compatibility across many applications.

The O-Pro™ Cartridge Seal

The O-Pro™ Cartridge seal replaces packing or mechanical seal by using O-Rings on the bracket seal chamber bore ID and along the shaft, allowing for an easy retrofit for a leaking pump. Similar to the O-Pro Guard seal, stainless steel construction provides wide ranging compatibility across many applications.

Key Products

- Ampco Sanitary Products - Sanitary Positive Displacement and Centrifugal Pumps

- Flux - Sanitary Drum Pumps

- Moyno - Sanitary Progressing Cavity Pumps

- Versamatic - FDA Compliant Air Operated Double Diaphragm pumps

- Viking Pump - Viking’s Heavy Duty Series Pumps with Patented O-Pro™ Seal Technology

- Viking Pump Wright Flow Technologies - Viking Pump’s Hygienic Positive Displacement and Centrifugal Pumps

- Warren Rupp Sandpiper - FDA Compliant Air Operated Double Diaphragm Pumps

Viking Pump Offerings for High Fructose Corn Syrup Applications

Viking Internal Gear, Positive Displacement Pumps are the industry standard for High Fructose Corn Syrup applications. Check out the video below to gain valuable insight into Viking’s Pumps, optimized for handling this widely used sweetener.

Case Study: Chocolate Plant Adopts O-Pro Barrier Technology to Eliminate Leakage & Minimize Downtime

A major producer of chocolate confections in the eastern United States had been operating many Viking pumps on a variety of confectionary liquids for decades.

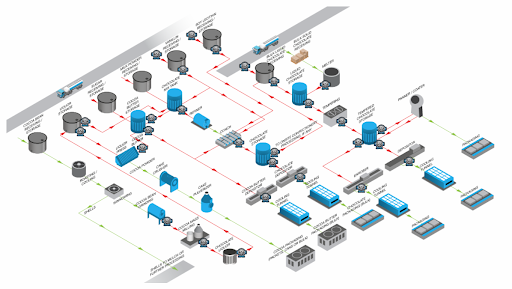

Typical Chocolate Plant Process Map

Contact us to discuss your application