When replacing a pump, doing a starting up, or operating a gear pump, it is critical to identify the correct rotation. In addition to not pumping in the desired direction, incorrect rotation can damage the pump or other equipment, and can result in unsafe operating conditions. Use the steps below to make sure you’re running your gear pump with the correct rotation.

Be sure to check our printable guide or if you’re heading in the field print out the pocket version here.

4 Steps to Identifying the Correct Rotation of a Viking Gear Pump:

- Check for rotation arrows. Some pumps have internal porting or other features which require the pump only operate in one direction. Bidirectional or reversible pumps, will not have an arrow; continue to step 2.

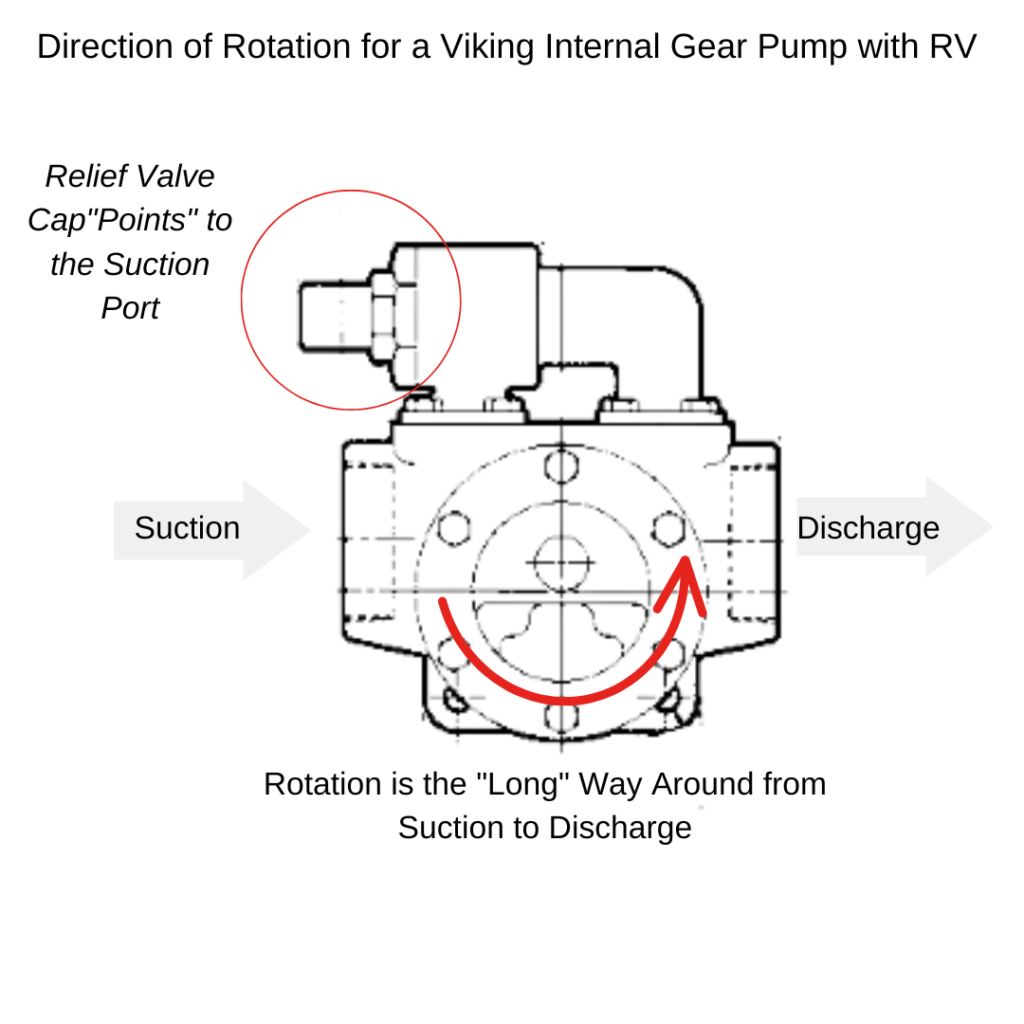

- Check for a Relief Valve. The relief valve cap will “point” to the suction port of the pump. It is important the relieve valve orientation match the pump rotation to prevent dangerously high pressures.

- Check the suction piping is connected to the suction port of the pump. If the pump does not have a relief valve or required rotation, so the pump is bi-directional, either port can be used as the suction port.

- Once you have identified the suction port of the pump, find the “long” way around from the suction port to the discharge port. This longer path will be in the direction of correct rotation.

Is the Pump Clockwise or Counterclockwise?

Shaft rotation is always as viewed from the shaft end of the pump. Note that port orientation can also vary, but the correct rotation will always move fluid on the longest path from the suction to the discharge. Note the pump in the diagram above is viewed from the head end, rather than the shaft end like the pump in the diagram below. Both these pumps have the same rotation: clockwise!

Other Tips:

- Many Viking pumps work equally well in both directions. Check out our guide on gear pump rotation changes to learn if your pump can be reversed.

- Some pumps, such as Viking Pump’s motor mounted Spur Gear pumps, can be rotated as a complete pump to reverse rotation. This can be particularly useful when the pump rotation cannot otherwise be reversed. Note, however, that the center line of the pump may change.

- Check that you have a pressure limiting relief valve able to relieve pressure from the discharge side of your pump. Relief valves may be integral or internal to the pump body, or may be externally mounted. Many gear pumps are capable of producing higher pressure than a system can contain, so it is important to have a properly installed and set relief valve.