Air-operated double diaphragm (AODD) pump failures can lead to significant environmental and financial consequences for manufacturers. When diaphragms rupture, the resulting spills create complex cleanup challenges and substantial costs. Understanding the Cost of Spills Spill cleanup typically involves using absorbent materials like oil-dry or kitty litter, followed by manual removal and disposal. The situation becomes … Continued

Centrifugal pumps are designed to move fluids, not air. When air becomes entrained in your pump system, it can lead to numerous operational issues and frustrations. If you suspect air might be causing problems in your pump, this guide will help you identify the symptoms and understand the common causes. The Impact of Air Entrainment … Continued

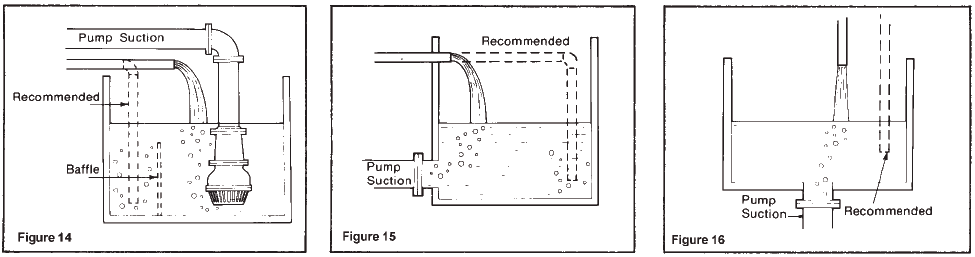

Is your pump making popping sounds or noise that resembles pumping marbles? You might be dealing with cavitation, a serious issue that can lead to increased energy consumption, excessive noise, and severe pump damage. Understanding Pump Cavitation Causes & Effects Cavitation occurs when bubbles form in the liquid around a pump’s impeller due to areas … Continued

When a centrifugal pump isn’t delivering adequate flow, it can impact both the pump itself and downstream process equipment. Use this guide to troubleshoot low flow conditions, so you can maintain optimal pump performance and protect connected process equipment. To troubleshoot low flow in centrifugal pumps, start by investigating these key issues: 1. Installation Issues … Continued

Per- and polyfluoroalkyl substances (PFAS) have earned the nickname “forever chemicals” due to their incredible persistence in the environment. These synthetic compounds, used in everything from non-stick cookware to waterproof clothing, pose significant health risks and environmental challenges. Recently, the U.S. EPA announced the final National Primary Drinking Water Regulation (NPDWR) for six PFAS and … Continued

In today’s industrial landscape, maintaining optimal gas pressure is crucial for many operations. Geiger Pump and Equipment Company’s specialists, with their heritage of quality systems from Gasho, design and manufacturer process gas booster systems that bridge the gap between available gas pressure and required pressure levels across various industries. Understanding Process Gas Booster Systems Process … Continued

Leverage VFDs in centrifugal pump systems to maximize energy savings, increase reliability and improve process control. This article, by Rebekah Macko, originally appeared in Pumps & Systems in December 2021. Variable frequency drives (VFDs) are often installed on a centrifugal pump with the intention that the drive will save energy, reduce wear, increase reliability and … Continued

A methanol metering system with ten pumps fed by three tanks with eight discharge points starts out as a neat set of simple lines on a process diagram. Designing and making the system a reality however, requires careful coordination of the needs of operators, maintenance personnel, the installing contractor, and specifying engineers. From assuring equipment … Continued

A cogeneration power plant in New Jersey approached our company with an urgent need for a large vertical turbine pump repair to be completed during their scheduled shutdown. As a trusted service provider, they requested our on-site support as a general contractor to ensure a seamless turnaround process. The plant faced significant pressure to restart … Continued

In honor of Earth Day (& month) we asked our customers what questions they had regarding their pump applications and how to make them more sustainable. So here are the answers you have been waiting for! How do I find out if my pump is operating at BEP? Choosing more efficient pumps are not only … Continued