A comprehensive failure analysis was conducted on a Goulds 3296 EZMAG magnetic drive pump following operational issues. The investigation was performed by our engineering team. Failure Analysis Findings The inspection revealed several critical issues related to extended dry run operation: Root Cause Of Goulds 3296 EZMAG Failure Based on the physical evidence, it was determined … Continued

You already know that non-OEM parts are typically cheaper, but do they really save you money in the long run? Let’s go over the facts. When maintaining or repairing your Goulds pump, one of the most critical decisions you’ll face is whether to purchase original equipment manufacturer (OEM) parts or opt for non-OEM alternatives. This … Continued

Emergency Goulds 3196 ANSI Pump Stock & Expert Service: How Geiger Restored Plant Operations Same-Day

When the call came in at 7:30 AM, we knew it was serious. One of the region’s busy manufacturing plants had shut down production because their longstanding (and critical) Goulds 3196 ANSI pump was down without backup. They called on Geiger’s technical expertise and on-hand inventory to get them back up and running. A Pump … Continued

Air-operated double diaphragm (AODD) pump failures can lead to significant environmental and financial consequences for manufacturers. When diaphragms rupture, the resulting spills create complex cleanup challenges and substantial costs. Understanding the Cost of Spills Spill cleanup typically involves using absorbent materials like oil-dry or kitty litter, followed by manual removal and disposal. The situation becomes … Continued

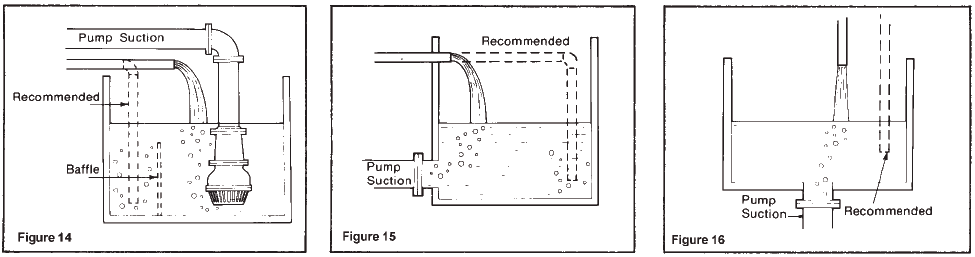

Centrifugal pumps are designed to move fluids, not air. When air becomes entrained in your pump system, it can lead to numerous operational issues and frustrations. If you suspect air might be causing problems in your pump, this guide will help you identify the symptoms and understand the common causes. The Impact of Air Entrainment … Continued

Is your pump making popping sounds or noise that resembles pumping marbles? You might be dealing with cavitation, a serious issue that can lead to increased energy consumption, excessive noise, and severe pump damage. Understanding Pump Cavitation Causes & Effects Cavitation occurs when bubbles form in the liquid around a pump’s impeller due to areas … Continued

Whether you need to buy a new ITT Goulds pump or a replacement part for an existing pump, the best place to find the ITT Goulds products you need is with us! Geiger Pump & Equipment Company is the exclusive stocking distributor for Goulds Pumps throughout areas in: For 40 years, Geiger has strived to … Continued

When a centrifugal pump isn’t delivering adequate flow, it can impact both the pump itself and downstream process equipment. Use this guide to troubleshoot low flow conditions, so you can maintain optimal pump performance and protect connected process equipment. To troubleshoot low flow in centrifugal pumps, start by investigating these key issues: 1. Installation Issues … Continued

Per- and polyfluoroalkyl substances (PFAS) have earned the nickname “forever chemicals” due to their incredible persistence in the environment. These synthetic compounds, used in everything from non-stick cookware to waterproof clothing, pose significant health risks and environmental challenges. Recently, the U.S. EPA announced the final National Primary Drinking Water Regulation (NPDWR) for six PFAS and … Continued

In today’s industrial landscape, maintaining optimal gas pressure is crucial for many operations. Geiger Pump and Equipment Company’s specialists, with their heritage of quality systems from Gasho, design and manufacturer process gas booster systems that bridge the gap between available gas pressure and required pressure levels across various industries. Understanding Process Gas Booster Systems Process … Continued